The battery is the essential part that helps you in starting up your vehicle. Its terminal is the only connection between a battery and an electrical device that uses the battery.

If your car’s battery terminal melted, it is not normal and should be repaired immediately. There are several reasons why your battery terminal might melt. One possibility is that your car’s battery might be overloaded with heavy things. And additionally, more reasons can be affected.

So Read further and know the main reasons behind your battery terminal melting and what to do to fix it.

What is a battery terminal?

The battery terminal (also known as an accumulator or starter battery) is a battery component that helps to connect the battery to the electrical system.

Battery terminals are linked between the battery and the electrical circuit, allowing for the flow of electrical current. Safe and efficient operation is dependent on them.

That is…

- The electrical connection of the battery with a starter and other current consumers.

- Ensure reliable electrical contact during the active operation of the vehicle in various conditions.

- Protection against an incorrect connection of the battery and also short circuits.

In the event of a malfunction, the terminals must be replaced, and to make the right choice of these parts, one should understand in detail their types, design, features, and applicability.

Types of Battery Terminals

There are several types of battery terminals available. Each with its own unique advantages and characteristics. Some of the most common types include:

Lead terminals

They are made of lead and have steel clamp screws and other parts. They are more compatible with battery terminals, but lead terminals have low mechanical strength and are easily melted in harmful environmental conditions.

Brass and bronze terminals

They are made of brass and bronze of certain grades and have high mechanical strength and low electrical resistance. However, they have a significant drawback – upon contact with a lead terminal, they form a galvanic couple, and chemical reactions occur between dissimilar metals, leading to the formation of oxides on the surface of the terminals. As a result, over time, the contact between the terminals deteriorates, and they are destroyed.

Brass terminals with tin-bismuth half.

They are made of brass and have a continuous coating of tin-bismuth or other solders, which reduces the intensity of chemical reactions when installed on a battery and extends the product’s life.

Copper terminals.

The best solution in terms of electrical characteristics, since copper, has a high electrical conductivity and practically does not affect the resistance of the circuit at any current.

Due to their disadvantages, gold-plated copper terminals are often used. These terminals are widely used today for car tuning – when installing high-end audio systems and other equipment.

Aluminum, zinc, and other terminals with a protective coating.

It is not a very common group of terminals. These terminals are light in weight, but they are expensive due to the presence of a coating, and their installation is not always justified.

Should be considered-

A well-functioning battery terminal ensures that the battery can supply sufficient power to the electrical circuit and recharge when necessary. On the other hand, a faulty battery terminal can lead to poor battery performance, including reduced power output and increased risk of electrical faults.

What would cause a battery terminal to melt?

Vehicles and electronic devices that use lead-acid batteries commonly experience battery terminal melting. This problem occurs when the metal post on the battery terminal overheats and melts, causing the battery cable to lose. It may cause power loss. As a result, the vehicle may have trouble starting or other electrical problems.

- Poor battery connections

The most common cause of battery terminal melting is poor or loss of battery connections. It can happen if the battery terminals are not tight enough or if the cable connections are dirty or corroded.

Also, old or corroded cables may have exposed wires at the ends, which can arc other metal parts. It also causes the battery terminal to melt.

- Excessive heat

Are you living in a country with a hot climate, and your car’s battery terminal melted, this may be a reason. Excessive heat generated by the vehicle’s engine or prolonged exposure to high temperatures can cause the battery terminal to melt. It is necessary to avoid exposing your device to ambient temperatures above 35° C (95° F).

If the car has to be parked for a long time in a hot place, it is best to use a Sun protection car cover. it will allow you to protect your car from both heat and sun radiation.

- Corrosion and Sulfation

Battery corrosion and Sulfation can increase the resistance between the battery and the terminal, which generates heat.

Then melts the terminal. It can be due to exposure to acidic substances or lack of proper maintenance.

- High current draw

Another cause of battery terminal melting is overcurrent draw, which can happen if the alternator or starter is not working correctly. In some cases, an overcharged alternator can also cause the battery terminal to melt, which generates excessive heat and causes the battery terminal to melt.

- Battery placement errors

Replacement batteries can vary in size and height, although engine compartment designs allow safe battery placement that does not cause electrical shorts.

A battery too close to the hood will short the battery terminals when the hood is closed. It could be melting the battery terminal. It can affect especially aftermarket batteries that come with a plastic base.

- Jumper cables to the wrong battery terminals

Battery terminals can also melt if jumper cables are connected to the wrong terminals.

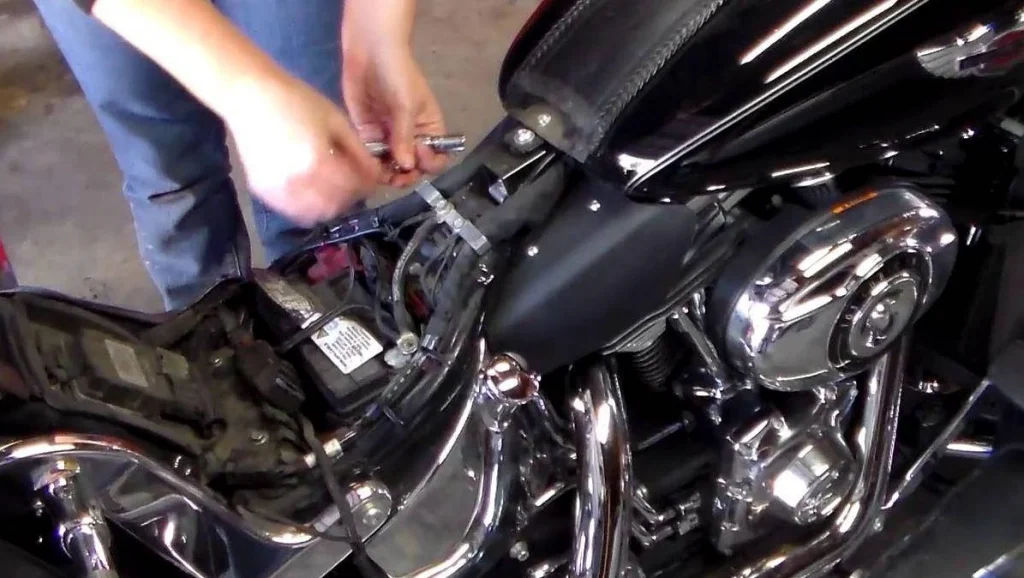

Why battery terminal melted on motorcycle?

Battery terminal melting is common in motorcycles owners like cars. The above-mentioned loose connections, high resistance, and corrosion are prominent reasons for battery terminal meltdown.

How many watts in a 12-volt battery – Unlocking the Mystery of 12v Battery Capacity

battery principles

How to fix a melted battery terminal?

There are generally two ways to restore melted battery terminals. We will consider them and evaluate the advantages and disadvantages of each method.

A damaged terminal and old lead should be thoroughly cleaned of burn or oxide before reconditioning, then you can proceed with the recovery process.

For each of the methods, we need a lead. It can finish off from fishing sinkers, but if they are not available, you can take a solder with a high lead content, for example, POS-15, POS-25, or any other, where there is more lead than tin. It is also desirable to have a knife, a file and fine sandpaper, pliers, and a tin can (for coffee, beer, and any kind in general).

From the tin, cut out the shape for the future terminal. Now use the entire terminal and the actual terminal strip (which will be placed on the damaged one). Make a mold, and align its walls. So that it is in maximum contact with the terminal block. By the way, the terminal block itself, before proceeding with the procedures, must be unclenched.

Now we can start fixing.

First Method

- Melt the lead over an open fire.

- Install the recovery form on the damaged terminal.

- Pour the lead into the mold.

- When it cools and hardens, remove the tin.

- Clean the terminal with a file to a shine. It should be in perfect contact with the terminal block.

The advantage of this method is its simplicity. You can melt lead even on a normal flame. Even if there is such a problem on the road, there is no problem if you find some branches and set them on fire.

The disadvantage is that if the lead for recovery and the actual lead at the terminal has a different composition after a few times lead may fall or scatter. It is only suitable if there are no other methods for restoring.

Second method

This method required several batteries, a thick copper wire with insulation, and a crocodile clip.

- First, Connect the wire to the crocodile.

- Disassemble the AA battery with a knife and pliers and remove the carbon rod.

- Connect it to the free end of the wire. This entire structure must connect to the battery terminal.

- Install the recovery form on the damaged one.

- Throw a few pieces of lead into the mold and place the connected rod. Don’t worry, it will spark, heat up and melt.

- Gradually fill the mold.

- Stir it with the rod so, the terminal’s metal mixes with the one you are adding.

- Clean it when the terminal is welding.

The advantages of this method are:

- If the lead is mixed, the terminal will be homogeneous and strong. So it won’t dissolve or collapse.

- The whole process can finish in little time.

- The finished wire with a carbon rod can be put in a toolbox and taken with you.

If you want to avoid melting or destroying the terminal, firmly attach the terminal block to it. Because poor connections may cause a spark, and It melts as a result.

Also, any oil type, for example, Litol, can be applied to the restored terminal, which prevents terminal oxidation.

The disadvantages of this method are:

- If there is a problem with the terminal on the way – you need to get a battery somewhere.

- As the battery charge consumes very quickly, it is critical to complete all surface manipulations as soon as possible.

Keep in mind

Make sure the battery terminals do not touch the hood. Remove the plastic base if necessary. Purchase protective caps for the battery terminals.

Why Battery Voltage Dropping While Driving – Explored in Detail

Battery principles

Final thoughts

Battery terminal melting is a common problem in vehicles with lead-acid batteries and other electronic components powered by lead-acid batteries.

To prevent this it is advisable to regularly check the tightness of the battery connections, keep the battery and its terminals clean, and ensure that the battery is located in a well-ventilated area that is not exposed to excessive heat. Also, it is important to use sun protectors when parking in a place with a lot of sunlight.

Finally, battery terminal melting is a common problem that can be avoided with routine maintenance, proper installation, and the use of high-quality materials. By following these instructions, you can keep your battery in peak operating condition for a long time.